Data dive: US, Canadian biodiesel producers readily meet quality metrics

- Ron Kotrba

- Jan 22, 2021

- 6 min read

Updated: Jan 25, 2021

Teresa Alleman, a senior fuel chemist with National Renewable Energy Laboratory, revealed the latest U.S. and Canadian biodiesel fuel quality survey results at the 2021 Virtual National Biodiesel Conference & Expo in January. The relatively new BQ-9000 quality survey is a collaboration between the National Biodiesel Board, NREL and participating BQ-9000 biodiesel producers in Canada and the U.S. Last year, in Tampa, Florida, Alleman shared results from the first such survey, which analyzed data from the two-year period of 2017-’18. For the latest survey, participating companies were asked to voluntarily provide their data from 2019. The results demonstrated that biodiesel producers are readily meeting the quality metrics, Alleman said.

The BQ-9000 biodiesel quality program is administered by the National Biodiesel Accreditation Commission. The nearly 50 biodiesel manufacturing plants are accredited by the producer arm of the BQ-9000 program—there are also marketing, retail and lab programs as well—and these production facilities are responsible for the majority of biodiesel fuel volumes on the U.S. and Canadian market. BQ-9000 requires monthly reporting of data parameters. Producers voluntarily sent their data to NBB and it was anonymized and randomized.

Metal content in biodiesel fuel—residual sodium or potassium from catalysis and calcium or magnesium from filtering and cleaning—is one of the most important, and one of the most OEM-scrutinized, parameters looked at today. Future NOx emissions from diesel vehicles will undergo another major reduction driven by regulations and implemented through the use of even more advanced, sensitive aftertreatment designs. These systems will likely utilize close-coupled SCR systems, the catalysts in which are extremely sensitive to metals contamination. Ash build-up in diesel particulate filters is also a big concern, considering new regulations could more than double the useful life of these systems.

The metals limit in the ASTM D6751 biodiesel fuel quality standard for combined sodium and potassium is 5 parts per million (ppm); for combined calcium and magnesium, the limit is also 5 ppm.

For 2019, the average for sodium and potassium content was 0.60 ppm. This was down from 0.68 ppm and 0.69 ppm in 2017 and 2018, respectively. For 2019, 383 data points were analyzed for sodium and potassium. The median was 0.26 ppm and 95 percent of all samples were at or under 2.42 ppm. Only one of 383 samples hit the upper threshold of 5 ppm. The vast majority—244—were listed as having no sodium and potassium.

For calcium and magnesium, it’s an even better story. Out of 381 samples, the average was 0.22 ppm, the median 0.05 ppm, and the 95th percentile was 1.10 ppm. Of the 381 samples tested for calcium and magnesium, 334 showed no presence of the metals. The max was 3.4 ppm.

Of 361 samples analyzed for phosphorous, 302 tested at zero levels. Eight samples, however, did test at the spec limit of 10 ppm. The average though was a low 0.46 ppm, up slightly from 2017-’18. The 95th percentile was 3 ppm, notably higher than the previous years’ results of around 1 ppm.

The minimum flashpoint for biodiesel in D6751 is 93 degrees Celsius. For 2019, of 479 samples, the average was 152 C, with a minimum and maximum at 95 C and 200 C, respectively. The median was 157 C. Since the flashpoint spec is a minimum rather than a maximum threshold, the fifth percentile (vs. 95th percentile) was 105 C, meaning 95 percent of the data was above 105 C. The 2018 data from the year prior showed one sample coming in at below the minimum, at 89 C. None from the 2019 data, however, showed this.

Not every lot is tested for methanol content, according to Alleman, but since this was such an important issue in Minnesota in the mid-2000s when the state was first in the nation to implement a B2 mandate, it is worth showing the data. Of the 197 samples tested for methanol content, five hit the spec limit of 0.20 percent. The average was 0.07 percent, and the 95th percentile was 0.14 percent. The minimum and maximum was zero and, again, 0.20 percent. None of the 197 samples analyzed was above the limit.

The max for water and sediment in D6751 is 0.050 percent. For the 2019 data analyzed, of 295 samples, the average was 0.002 percent, with a vast majority—234—coming in at zero percent. Thirty-nine samples tested at 0.010 percent. The max was 0.025 percent. The 95th percentile was 0.010 percent.

“All samples are meeting ‘workmanship’ (clear and bright),” Alleman said, “and they are at the quality level set and expected for biodiesel.”

The D6751 spec has no cloud-point requirements since it is a feedstock-neutral quality spec, and biodiesels from a variety of feedstocks will naturally display a variety of cloud points. For 2019 data, of 523 samples, the minimum cloud point tested was minus 6 C. The max was 15.8 C. The average was 0.96 C. The 95th percentile was 10 C. Median temperature was 0 C.

On acid number and oxidation stability, data results from 2019 were very positive. The specification limit on acid number is 0.50 mgKOH/g. Of the 521 samples analyzed, the minimum acid number was 0.07, the maximum tested was 0.49 (just under the spec limit), the average was 0.27, the median was also 0.27, and the 95th percentile was 0.43. One sample in in 2018 was off-spec at 0.51. None in the 2019 data set failed.

B100 has a minimum oxidation stability spec of 3 hours in the Rancimat test under D6751. Of 523 samples analyzed, the minimum was 3.8 hours, the maximum was 24.2 hours, the average was 9.1 hours, and the median was 8.5 hours. Like flashpoint, oxidative stability has a minimum, not a maximum, limit so instead of using the 95th percentile to show where a vast majority of the data lies, a fifth percentile better represents the relevant information. The fifth percentile for oxidative stability is 5.3 hours, meaning 95 percent of the 523 samples demonstrated 5.3 hours or longer shelf life in the accelerated test—a very positive finding. In the 2017 data presented last year, one sample failed. None of the samples for 2019 failed.

The limit on free glycerin in D6751 is 0.20 percent and only two of 490 samples in the 2019 data set were at the threshold limit. None of them was over, and both the median and average was 0.005 percent free glycerin. Of the 490 samples, 136 were at zero percent. The 95th percentile was 0.013 percent. In the 2017-’18 data, a few samples were off-spec on free glycerin.

The limit on total glycerin is 0.240 percent. While one sample in 2017 failed, none of the 523 samples in 2019 tested above the limit. At the two extremes, 56 were at zero percent and three were at 0.21 percent. The max was 0.228 percent and the average was 0.094 percent. The median percentage was 0.101 and the 95th percentile came in at 0.171.

There is no monoglyceride spec for No. 2-B grade B100 in D6751, but there is a 0.40 percent max for No. 1-B. Of 511 samples, the minimum for monoglycerides was 0.008 percent, the max was 0.666 percent and the average was 0.269 percent. The median was 0.309 percent and the 95th percentile for monoglycerides was 0.418 percent. “This is showing the high-quality data and the high-quality product that was produced in 2019,” Alleman said.

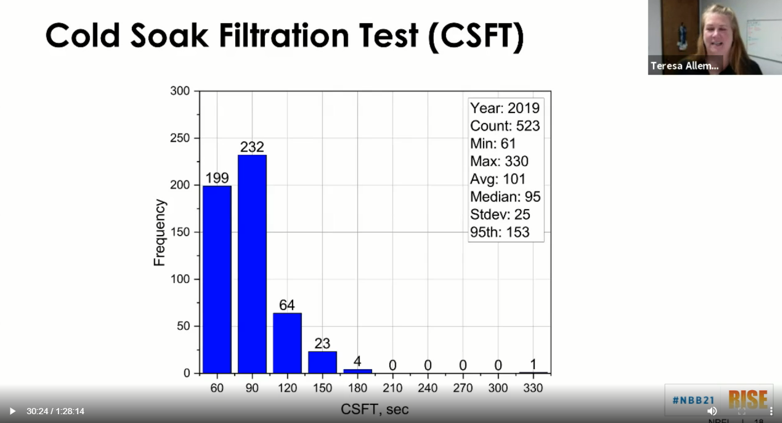

No. 1-B grade biodiesel has a 200-second maximum time limit in the Cold Soak Filtration Test whereas No. 2-B grade biodiesel has a 360-second max. “I can tell you more than you’ll ever want to know about this test,” Alleman said. “I really am very pleased to report the [results].” Quality issues in the mid- to late 2000s led to the development and inclusion of this test and parameter in D6751.

Of 523 samples in the 2019 dataset, the minimum CSFT result was 61 seconds and the maximum was 330 seconds. While it is not known which samples were which grade, none of the samples failed the 360-second max for No. 2-B grade biodiesel. The average was 101 seconds and the median was 95 seconds. Nearly half of the samples (232 of 523) were at the 90-second mark, well below the 200-second max for No. 1-B grade. The 95th percentile was 153 seconds.

The 2019 sulfur results were also very positive. Of 501 samples, 162 came in at zero ppm. While it is unknown which samples were intended for which markets (on-road limits are 15 ppm while other markets may allow up to 500 ppm), only one sample of 501 hit the upper threshold of on-road limits at 15 ppm. The average was 4.1 ppm and the median was 2.8 ppm. The 95th percentile was 11.8 ppm.

Alleman highlighted just how positive and remarkable these results are. “Quality is very stable,” she said. “There aren’t a lot of changes year to year [from 2017-’19], which speaks to the incredible efforts from biodiesel producers in the U.S. and Canada. There’s not a whole lot to say. Producers are readily meeting these quality metrics.”

After the event, Alleman told Biobased Diesel Daily, “There is nothing about this data that concerns me.”